Products

A high performer in small series production, Royalstampi has continuously developed its know-how, not just with regard to all the glass shaping processes (blow and blow, press and blow), but also in terms of new markets. In fact, the skills acquired over the years have permitted the company to expand its production to the manufacture of aluminum molds for plastic containers.

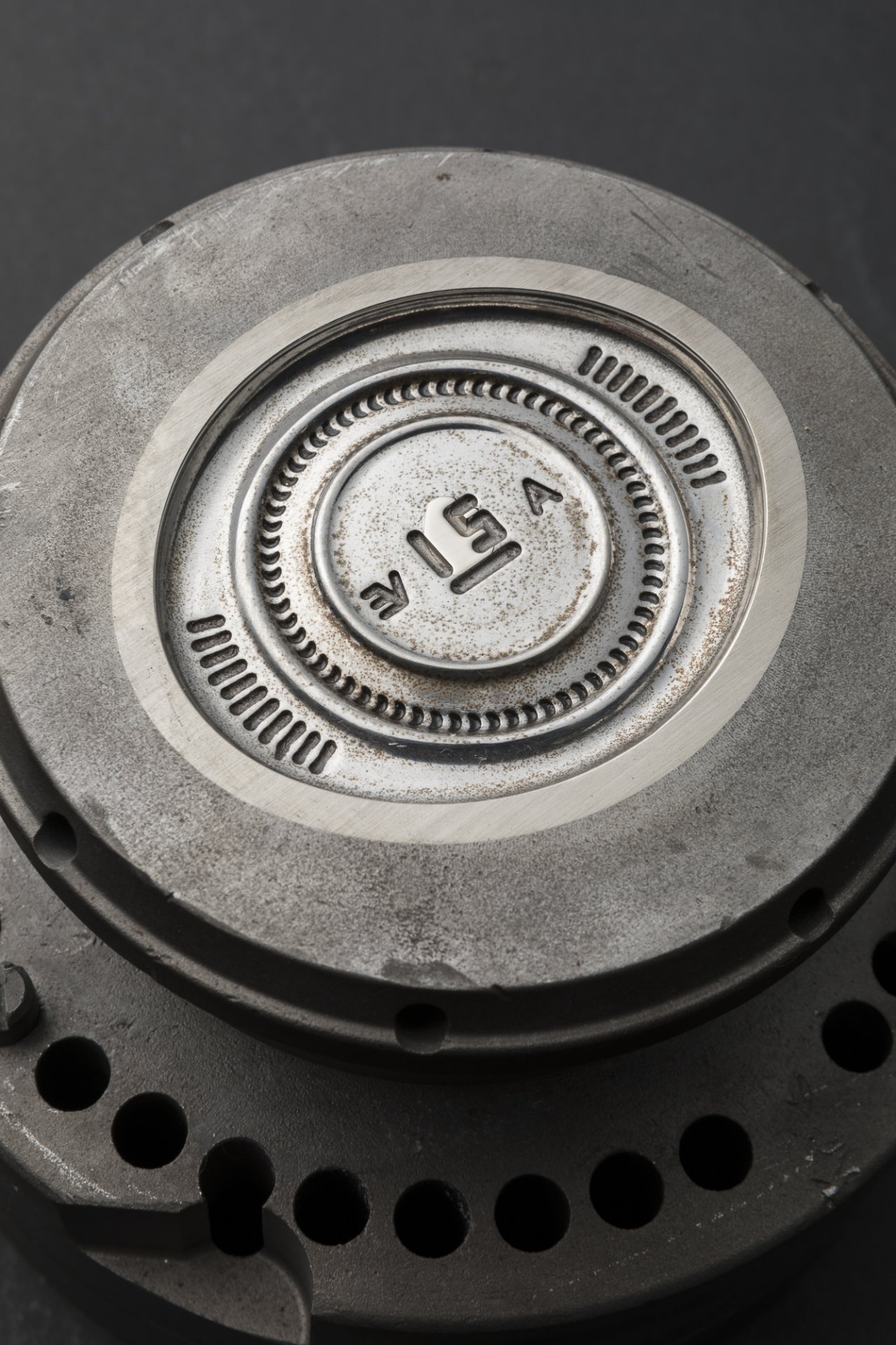

Royalstampi makes molds for various sectors and in different materials, from cast iron to bronze, which can also be personalized according to the client’s specific requirements.

Everything begins with the design and development of the toolpath for the various activities and then moves on to the roughing out and preparation for welding. The finishing of the surfaces and the inner profile is then carried out on the warm mold. The external diameters as well as the neck and base are turned. The subsequent phases are verti-flow drilling and manual drilling followed by the polishing of the inner profile, which comes into contact with the glass, and the drilling of the air outlet. Finally, everything is assembled and carefully checked again.

A similar process is followed for the design and realization of aluminum molds for molding plastic materials.

Royalstampi also designs and creates variable elements, stars, and guides for inspection machinery in the glass and plastic packaging sectors and for the bottling sector. The workshop develops and constructs the components starting from the client’s request, and then interacts with the client to propose personalized solutions. RoyalStampi’s production flexibility guarantees delivery of the finished product within 48 hours.